_Reflow Soldering Monitoring Software’s Scalability, Extreme Traceability Recognized _

_for Importance to Industry_

October 6, 2020 – OvenSENTINEL(tm) [1], ECD’s distinctive reflow soldering continuous monitoring technology, was honored with a Global Technology Award just as its second-generation version is set to hit the market. The award ceremony, which took place virtually last month, highlighted OvenSENTINEL’s top ranking in the process control software category based on the innovation’s unique feature set.

October 6, 2020 – OvenSENTINEL(tm) [1], ECD’s distinctive reflow soldering continuous monitoring technology, was honored with a Global Technology Award just as its second-generation version is set to hit the market. The award ceremony, which took place virtually last month, highlighted OvenSENTINEL’s top ranking in the process control software category based on the innovation’s unique feature set.

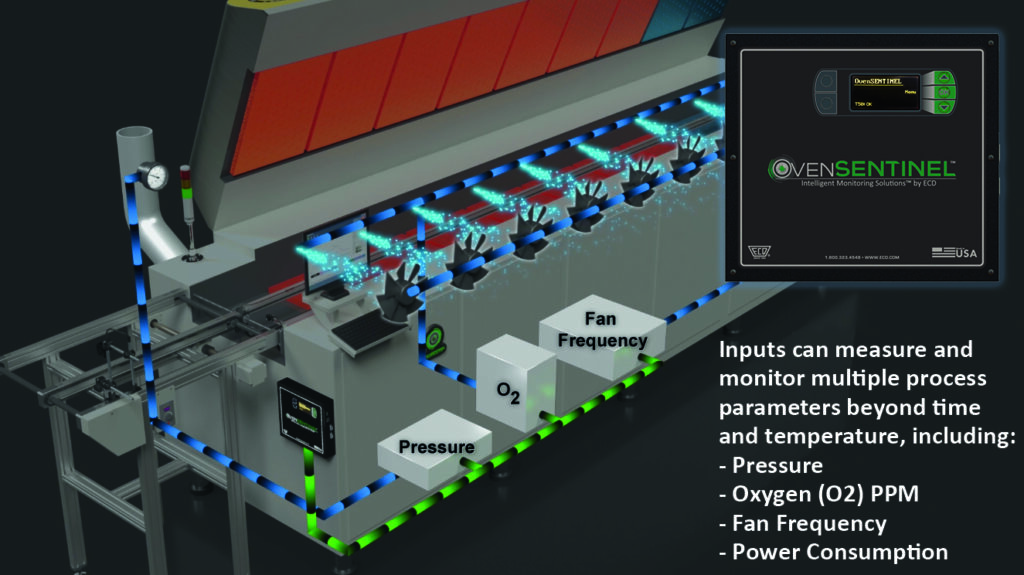

Differentiated from standard reflow monitoring systems, OvenSENTINEL can be customized to measure multiple aspects of the reflow process that may impact quality and reliability. Some of these include oxygen parts per million (ppm), convection fan speed, air pressure, exhaust flow or pressure, and energy consumption, to name a few. OvenSENTINEL’s extended measures allow for a more complete traceability record, providing proof that all critical aspects of the reflow process are working within specification.

Unique features of ECD’s next-gen OvenSENTINEL software include:

* Industry-first, extended sensor network with measurements that go well beyond temperature and conveyor speed.

* Integration with ECD’s powerful M.O.L.E. MAP Software offers expansive data with up to 20 thermocouple channels and hundreds of calculations available for unprecedented data detail.

* Dual-lane oven support and advanced automation.

* MSSQL database with human readable tables makes data access transparent and compatible with major MES systems

“ECD and its partners are grateful for the OvenSENTINEL Global Technology Award win and the industry value acknowledged by the judges,” shares ECD Electronics Division Manager, Mark Waterman. “As assemblies become more complex and profit margins tighter, effective process monitoring and automation are difference-makers. OvenSENTINEL’s capability enables reduced operational costs, expanded business insight, reduction of scrap and potential product recalls, and higher quality product output, among other advantages. For manufacturers of high-reliability assemblies, OvenSENTINEL is the traceability powerhouse required for compliance and competitiveness.”

The second-generation of OvenSENTINEL will be commercially available in October 2020. For more information about the technology or to schedule an online demo, visit https://ift.tt/3iAXJI0.

No comments:

Post a Comment